Manual Chapter :

Environmental Guidelines

Applies To:

Show Versions

Environmental Guidelines

General environmental and

installation guidelines

The

i15000 Series

platform is

an industrial network appliance that is designed to be mounted in a standard

19-inch EIA rack.Follow these guidelines to adhere to safety precautions:

- Install the rack according to the manufacturer's instructions and check the rack for stability before placing equipment in it.

- Build and position the rack so that after you install the platform, the power supply and the vents on both the front and back of the unit remain unobstructed. The platform must have adequate ventilation around the unit at all times.

- Although not required, a 1U space between units makes it easier for you to remove the unit from the rack in the event that the unit requires service. A 1U space between units also provides additional cable routing options.

- Leaving at least 100 mm of space from the front panel of the unit to the rack front or rack door provides enough room for you to route the cables without excessive bending or insulation damage.

- Do not allow the air temperature in the room to exceed 104°F (40°C).GR-63-CORE NEBS-compliant shelf units can operate at maximum air temperature of up to 131°F (55°C). Operation at the maximum temperature is supported on a short term basis, per GR-63-CORE.

- Do not plug the unit into a branch circuit shared by more electronic equipment than the circuit is designed to manage safely at one time.

- Route and secure power cords so that they do not obstruct removal of the fan tray.

Due to the weight of the platform, at least two people

are required to install this chassis into a rack. Failing to use two people

can result in severe personal injury or equipment damage.

This product is sensitive to electrostatic discharge

(ESD). F5 recommends that you use proper ESD grounding procedures and

equipment when you install or maintain the unit.

Customers should not attempt to replace batteries. There

is a risk of explosion if a battery is replaced with an incorrect type. Field

technicians should dispose of used batteries according to the

instructions.

Il y à risque d'explosion si la batterie

est remplacée par une batterie de type incorrect. Mettre au rebut les

batteries usagées conformément aux instructions.

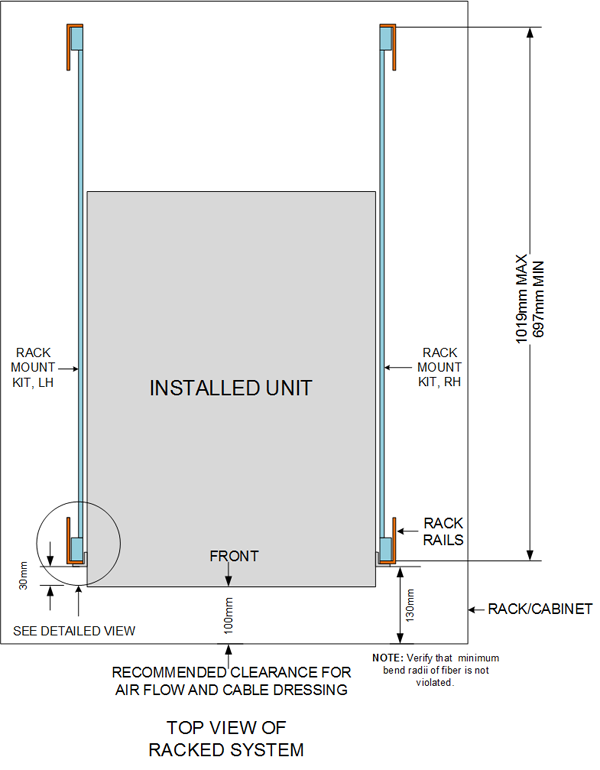

Chassis rack-mount spatial

requirements

The

i15000 Series

platforms ship with a rack mount kit to

help install the system more easily. This kit requires that the rack or cabinet

has certain clearances and spacing, as shown here.Rack mounting

spatial requirements for the

i15000 Series

platform

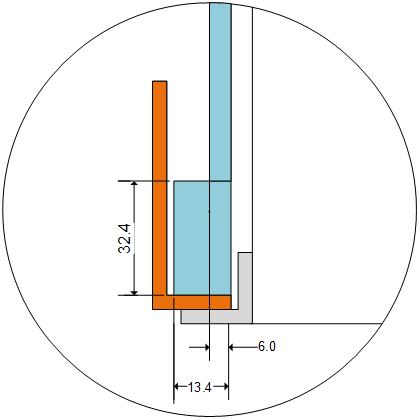

Detailed view of

rack mounting spatial requirements

Guidelines for power supply units (PSUs)

All iSeries platforms support either single or dual

power supply units (PSUs). When your system includes dual PSUs, both

supplies must be of the same type. To verify this, make sure that the

supplies have matching base part numbers (PWR-XXXX). You can find the base

part number printed on the label on top of the individual power

supply.

The full part number is a nine digit

number (PWR-XXXX-YY). The base part number is seven digits and must match,

but the suffix (-YY) does not need to match.

Example of label to check PWR-XXXX part

number

If you cannot read the base part number, ensure that the

pull handles are both in a

vertical

orientation and that the sheet metal on the power cord

face for each supply has the same perforation shapes.When you add or replace a PSU in your system, be sure to

verify the supply's features and that the PWR-XXXX part numbers match to

ensure that you have the correct supply.

Guidelines for AC-powered

equipment

An AC-powered installation must meet these requirements:

- Use a50amp external branch circuit protection device to install the unit.

- Use one power feed for each individual power supply.

The platform must be installed in a RESTRICTED ACCESS

LOCATION, such as a central office or customer premises environment.

The power cables included with this unit are for

exclusive use with this unit and should not be used with other electrical

appliances.

These guidelines apply to STATIONARY PLUGGABLE EQUIPMENT

TYPE A with simultaneous multiple connections to the AC MAINS SUPPLY:

- The building installation shall provide a means for connection to protective earth; and

- The equipment is to be connected to that means; and

- A SERVICE PERSON shall check whether or not the socket-outlet from which the equipment is to be powered provides a connection to the building protective earth. If not, the SERVICE PERSON shall arrange for the installation of a PROTECTIVE EARTHING CONDUCTOR from the separate protective earthing terminal to the protective earth wire in the building.

High leakage current. Earth connection essential before

connecting supply.

Guidelines for DC-powered equipment

A DC-powered installation must meet these

requirements:

- Use a 15 amp external branch circuit protection device to install the unit.

- For permanently connected equipment, incorporate a readily accessible disconnect in the fixed wiring.

- Use only copper conductors.

- Cabling for the system must be grounded on both sides.

- Use one power feed for each individual power supply.

Install DC-powered equipment only in restricted access

areas, such as dedicated equipment rooms, equipment closets, or similar

locations.

Installer le matérial alimenté par courant continu

uniquement dans des zones à accès reglementé, telles que des salles de

matériel, des armoires de materiel ou tout emplacement similaire.

Guidelines for NEBS platforms

This information applies to the Network Equipment-Building System (NEBS)

version of the this platform:

- This equipment meets NEBS requirements per GR-63-CORE.

- This equipment is suitable for installation in these locations:

- Network Telecommunication Facilities

- Locations where the National Electrical Code (NEC) applies

The intra-building

interfaces of this platform, including Ethernet, are suitable for connection to

intra-building or unexposed wiring or cabling only with shielded and grounded cables

at both ends. The intra-building ports of the equipment must not be connected

metallically to interfaces that connect to the outside plant (OSP) or its

wiring.

You should coat bare conductors with an appropriate

antioxidant compound before you make crimp connections. You should bring

all unplated connectors, braided strap, and bus bars to a bright finish

and then coat them with an antioxidant before you connect them.

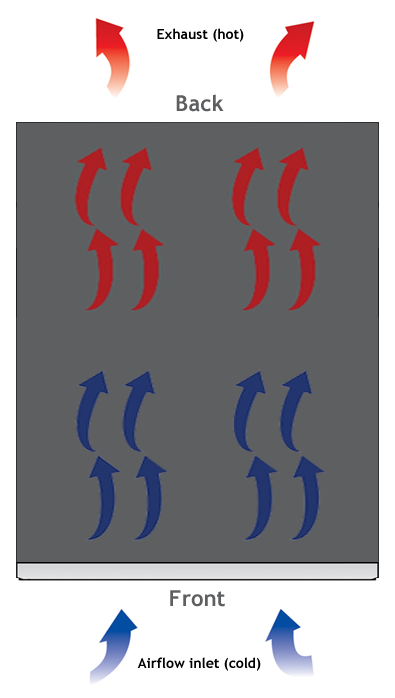

Platform airflow diagram

When you install the platform into a rack, it is important to understand

the unit's airflow direction so that you can ensure proper cooling.

The platform employs a negative pressure fan system, which draws cold air

in from the front of the chassis.

Airflow in iSeries

platforms