Manual Chapter :

Repackaging Guidelines

Applies To:

Show Versions

Repackaging Guidelines

About repackaging the platform

If it becomes necessary to transport the platform to another

location or return it to F5, these guidelines will help ensure that you

repackage the platform properly.

You can perform a disk erase operation to erase all sensitive data

from storage drives (for example, solid-state drives and hard disk drives)

before you return a platform to

F5

.

For more information, see F5 Platforms:

Essentials

at techdocs.f5.com/en-us/hw-platforms/f5-plat-hw-essentials.html.Before returning any equipment,

contact

F5

to obtain a Service

Order (SO) or Return Material Authorization (RMA) case number.You must use shipping materials and

packaging provided by

F5

when

repackaging the platform.Be sure to keep a record of the tracking

number and ship date. These will be needed to track lost shipments.

Do not include any cables, removable

transceiver modules, GBICs, or other peripheral items if you are returning the

platform to

F5

.Repackage the i15000 Series platform

The i15000 Series platforms must be

shipped in F5-provided packaging.

To ensure your safety

and to prevent damage to the platform, F5 strongly recommends that you have

at least two people remove the platform from the rack and repackage it

into the shipping box.

- Place the shipping box on the pallet.

- Halt the platform using the LCD panel.

- Disconnect the AC power cordor DC power terminalfrom the power supply units (PSUs).

- Disconnect the network cables and other cables from the chassis, and then remove any optical modules.

- Remove the chassis from the rack.

- Remove all installation hardware from the chassis.

- Line the bottom of the shipping box so that the wrapping sheet is open lengthwise.

- Lower the chassis onto the bottom foam in the shipping box, with the front of the chassis facing the side of the foam labeled FRONT, and then secure the wrapping sheet with a strip of packaging tape.

- Insert the front and rear foam pieces into the slots on the bottom foam.

- Place the accessory box in between the two foam pieces.

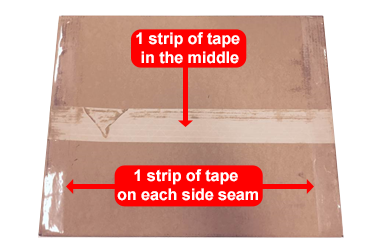

- Close and seal the shipping box with one strip of tape across the middle seam and one strip on each side seam.

- Place the longer edge protectors on the long sides of the box and the shorter edge protectors on the shorter side of the box, and then secure with 1/2 inch polypropylene strapping (600 lbs break strength).Straps must be tight enough that they do not slip when pulled to the side.

For the lengthwise strap, wrap around the pallet strings and double back. Do not feed the straps underneath the pallet.

For the lengthwise strap, wrap around the pallet strings and double back. Do not feed the straps underneath the pallet.