Applies To:

Show Versions

Platform Maintenance

About maintaining the platform

The VIPRION® 2400 platform contains several components that you can replace individually without exchanging the entire system. This platform contains these replaceable components:

- AC power supply

- DC power supply

- Fan tray

- Storage drive assembly

Note: Applies only to the B2100 blade with hard disk drive (HDD).

- Blades

About AC power supplies

The VIPRION® 2400 platform supports one to two hot swappable AC power supplies. The power supplies are auto-ranging from 100-127VAC to 200-240VAC input.

The platform supports power redundancy, which ensures that the system is unaffected if a single power supply fails in a system containing more than one power supply.

A power supply partially removed from the platform

Removing a power supply

Installing a power supply

About DC power supplies

The VIPRION® 2400 platform supports up to two hot swappable DC power supplies.

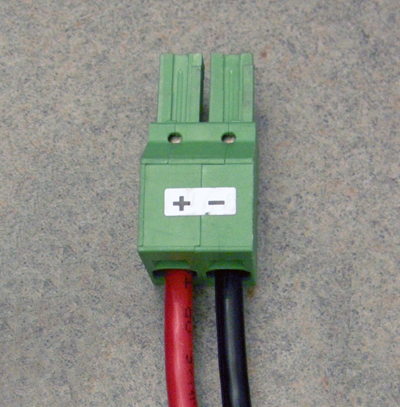

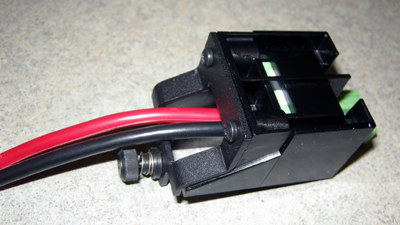

The platform supports power redundancy, which ensures that the system is unaffected if a single power supply fails in a system containing more than one power supply. The DC power supply includes a DC input connector, which is composed of a DC lock assembly and a DC plug. Connect the wires from the DC power source to the DC input connector, and then insert the connector into the DC power supply.

The DC power supply does not have an on/off switch. You can control the power from the rack switch or the DC power source.

Removing a power supply

Installing a DC power supply

Wiring the DC connector

You will need these components to wire the DC power supply:

- Wire stripping tool

- Two 6 AWG copper wires long enough to reach from the platform to the DC power source

VIPRION 2400 DC power supply, lock assembly, and plug

Connecting DC power to the platform

About the fan tray

The VIPRION® 2400 platform has a removable fan tray that is designed to maintain airflow throughout the chassis. You can change or replace the fan tray as part of the routine maintenance of the unit, or in the event of a fan failure. The fans in the fan tray run constantly while the unit is on. Over time, the fans can wear out, requiring you to replace the fan tray.

Fan tray in the platform

Replacing the fan tray

About the storage drive assembly

By default, VIPRION® B2000 Series blades contain one storage drive assembly that contains either one hard disk drive (HDD) or one solid-state drive (SSD).