Applies To:

Show Versions

Environmental Guidelines

General environmental and installation guidelines

The VIPRION® 4800 platform is an industrial network appliance that is designed to be mounted in a standard 19-inch EIA rack. Follow these guidelines to adhere to safety precautions:

- Install the rack according to the manufacturer's instructions and check the rack for stability before placing equipment in it.

- Build and position the rack so that once you install the platform, the power supply and the vents on both the front and back of the unit remain unobstructed. The platform must have adequate ventilation around the unit at all times.

- Although not required, a 1U space between units makes it easier for you to remove the unit from the rack in the event that the unit requires service. A 1U space between units also provides additional cable routing options.

- Use an open-style rack or cabinet to reduce the restrictions to airflow. Use of a closed cabinet is not recommended. If a closed cabinet must be used, pay special attention to ensuring that there is adequate airflow on the front and rear of the chassis, as well as in and out of the cabinet.

- The installation should be set up in a hot aisle-cold aisle configuration. Be sure to minimize leakage between the two sides.

- Block off empty rack spaces to prevent back-to-front leakage of air flow. Recirculation of hot discharge air to the chassis air inlet will greatly impede the system cooling efficiency.

- Ensure that your cabinet and data center arrangement has adequate air flow to minimize back pressure on the discharge side of the system. Restricting flow causes the chassis to run hotter than it needs to.

- Use good cable dressing practices to help minimize detrimental effects on chassis cooling by reducing the amount of restriction to the chassis inlet. The VIPRION 4800 platform comes provided with cable managers. Avoid having cables hang in front of the chassis air inlet.

- Do not allow the air temperature in the room to exceed 104°F

(40°C).

Note: NEBS-certified platforms can withstand air temperatures up to 131°F (55°C). The maximum temperature is only required to be met for a short period of time.

- Do not plug the unit into a branch circuit shared by more electronic equipment than the circuit is designed to manage safely at one time.

Guidelines for the AC-powered platform

An AC-powered installation must meet these requirements:

- Install the unit using a 20 amp external branch circuit protection device.

- Normally, one power feed is used for each individual power supply.

The power requirements for the chassis are: 200-240 VAC ~, 50-60 Hz 16A Per Cord, Max 32 A total.

- The building installation shall provide a means for connection to protective earth; and

- The equipment is to be connected to that means; and

- A SERVICE PERSON shall check whether or not the socket-outlet from which the equipment is to be powered provides a connection to the building protective earth. If not, the SERVICE PERSON shall arrange for the installation of a PROTECTIVE EARTHING CONDUCTOR from the separate protective earthing terminal to the protective earth wire in the building.

Guidelines for the DC-powered platform

A VIPRION® DC-powered installation must meet these requirements:

- Install the unit using a 100 amp external branch circuit protection device.

- One power feed must be used for each individual power supply.

- For permanently connected equipment, incorporate a readily accessible disconnect in the fixed wiring.

- Use only copper conductors.

- The DC MAINS powering the equipment shall be connected to protective earth.

The power requirements for the chassis are: 44-72 VDC, 62 A Per Cord, Max 124 A total.

NEBS platform guidelines

This information applies to the Network Equipment-Building System (NEBS) version of the VIPRION 4800 Series platform.

This equipment meets NEBS requirements per GR-63-CORE.

This equipment is suitable for installation in these locations:

- Network Telecommunication Facilities

- Locations where the National Electrical Code (NEC) applies

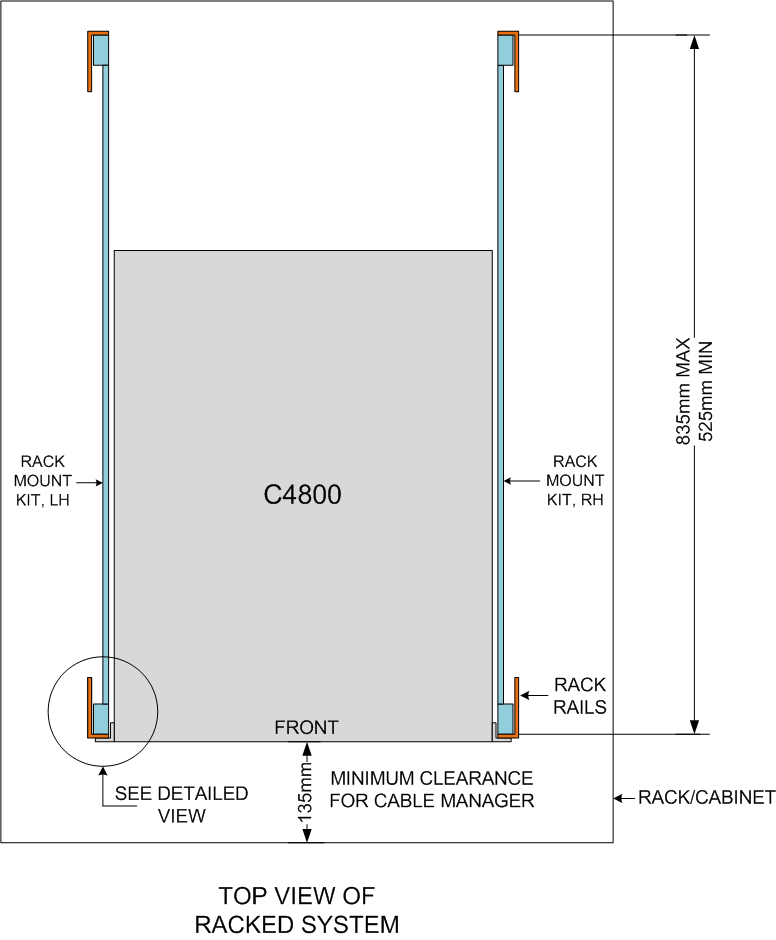

Chassis rack mount spatial requirements

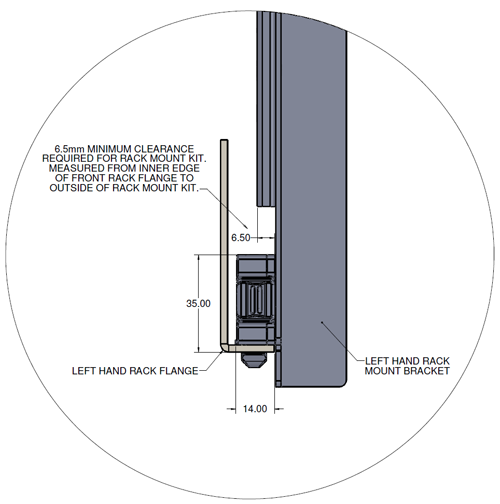

The VIPRION® 4800 platform ships with a rack mount kit to help install the large system more easily. This kit requires that the rack or cabinet has certain clearances and spacing, as shown here:

Spatial requirements for rack mounting the VIPRION 4800 platform

Detailed view of spatial requirements for rack mounting the VIPRION 4800 platform

Platform power and airflow

The system installation needs to consider the power and air flow specifications of all installed equipment to ensure proper cooling. Although the maximum specifications for the VIPRION® 4800 chassis are listed here, the actual power and airflow vary depending on how the system is configured, the operating load, and the operating environment.

| Max power | ~5500W |

| Max airflow | ~2200 cfm |

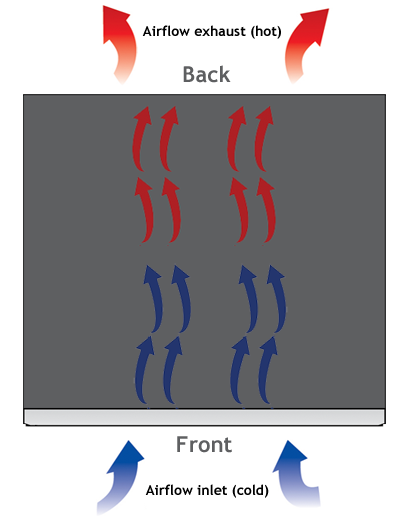

Platform airflow diagram

When you install the platform into a rack, it is important to understand the unit’s airflow direction so that you can ensure proper cooling.

The platform employs a negative pressure fan system, which draws cold air in from the front of the chassis and exhausts hot air out the back of the chassis.

Airflow in the VIPRION 4800 platform