Manual Chapter :

Environmental Guidelines

Applies To:

Show Versions

Environmental Guidelines

General

environmental and installation guidelines

The VELOS Series platforms are industrial

network devices that are designed to be mounted in a standard 19-inch EIA

rack.

Follow these guidelines to adhere to safety

precautions:

- Install the rack according to the manufacturer's instructions and check the rack for stability before placing equipment in it.

- Build and position the rack so that once you install the platform, the power supply and the vents on both the front and back of the unit remain unobstructed. The platform must have adequate ventilation around the unit at all times.

- Use an open-style rack or cabinet to reduce the restrictions to airflow. Use of a closed cabinet is not recommended. If a closed cabinet must be used, pay special attention to ensuring that there is adequate airflow on the front and rear of the chassis, as well as in and out of the cabinet.

- The installation should be set up in a hot aisle-cold aisle configuration. Be sure to minimize leakage between the two sides.

- Block off empty rack spaces to prevent back-to-front leakage of air flow. Recirculation of hot discharge air to the chassis air inlet will greatly impede the system cooling efficiency.

- Ensure that your cabinet and data center arrangement has adequate air flow to minimize back pressure on the discharge side of the system. Restricting flow causes the chassis to run hotter than it needs to.

- Use good cable dressing practices to help minimize detrimental effects on chassis cooling by reducing the amount of restriction to the chassis inlet. Avoid having cables hang in front of the blade air inlet.

- Do not allow the air temperature in the room to exceed 104°F (40°C).NEBS-compliant platforms can withstand air temperatures up to 131°F (55°C) for short periods of time.

- Do not plug the unit into a branch circuit shared by more electronic equipment than the circuit is designed to manage safely at one time.

Due to the weight of the platform, it is recommended that you use a lift to transport and install the chassis. The lift handles on the chassis can support the weight of an empty chassis, but it is recommended to only use them to maneuver the chassis on and off of the lift. Manually lifting the chassis risks personal injury.

This product is sensitive to electrostatic discharge (ESD). F5 recommends that you use proper ESD grounding procedures and equipment when you install or maintain the unit, including attaching a ground strap to the ground strap receptacle location on the front left side of the chassis.

Customers should not attempt to replace batteries. There is a risk of explosion if a battery is replaced with an incorrect type. Field technicians should dispose of used batteries according to the instructions.

Il y à risque d'explosion si la batterie

est remplacée par une batterie de type incorrect. Mettre au rebut les

batteries usagées conformément aux instructions.

Guidelines for AC-powered equipment

A VELOS AC-powered installation must meet these requirements:

- Install the unit using a 20 amp external branch circuit protection device.

- One power feed must be used for each individual power supply.

The power requirements for the chassis are:

- CX410 chassis: 200-240 VAC #, 50-60 Hz, 16A per cord, max 32A total

- CX1610 chassis: 200-240 VAC #, 50-60 Hz, 16A per cord, max 96A total

The platform must be installed in a RESTRICTED ACCESS LOCATION, such as a central office or customer premises environment.

The power cables included with this unit are for exclusive use with this unit and should not be used with other electrical appliances.

製品には、同梱された電源コードセットを使用すること及び同梱された電源コー ドセットは、他の製品に使用しないこと.

These guidelines apply to STATIONARY PLUGGABLE EQUIPMENT TYPE A with simultaneous multiple connections to the AC MAINS SUPPLY:

- The building installation shall provide a means for connection to protective earth; and

- The equipment is to be connected to that means; and

- A SERVICE PERSON shall check whether or not the socket-outlet from which the equipment is to be powered provides a connection to the building protective earth. If not, the SERVICE PERSON shall arrange for the installation of a PROTECTIVE EARTHING CONDUCTOR from the separate protective earthing terminal to the protective earth wire in the building.

High leakage current. Earth connection essential before connecting supply.

Guidelines for DC-powered equipment

A VELOS DC-powered installation must meet these

requirements:

- Install the unit using a 100 amp external branch circuit protection device.

- One power feed must be used for each individual power supply.

- For permanently connected equipment, incorporate a readily accessible disconnect in the fixed wiring.

- Use only copper conductors.

- The DC MAINS powering the equipment shall be connected to protective earth.

The power requirements for the chassis are:

- CX410 chassis: 40-72VDC, 85A per cord, max 170A total

- CX1610 chassis: 40-72VDC, 85A per cord, max 510A total

Install DC-powered equipment only in restricted access areas, such as dedicated equipment rooms, equipment closets, or similar locations.

Installer le matérial alimenté par courant continu

uniquement dans des zones à accès reglementé, telles que des salles de

matériel, des armoires de materiel ou tout emplacement similaire.

Guidelines for NEBS platforms

This information applies to the Network

Equipment-Building System (NEBS) version of this VELOS Series

platform:

- This equipment meets NEBS requirements per GR-63-CORE and GR-1089-CORE.

- This equipment is suitable for installation in these locations:

- Network Telecommunication Facilities

- Locations where the National Electrical Code (NEC) applies

The intra-building interfaces of

this platform, including Ethernet, are suitable for connection to

intra-building or unexposed wiring or cabling only with shielded and

grounded cables at both ends. The intra-building ports of the equipment

must not be connected metallically to interfaces that connect to the

outside plant (OSP) or its wiring.

You should coat bare conductors with an appropriate antioxidant compound before you make crimp connections. You should bring all unplated connectors, braided strap, and bus bars to a bright finish and then coat them with an antioxidant before you connect them.

Optical temperature alarms may be displayed prior to system

warnings. Refer to optical vendor information for operating temperature

guidelines.

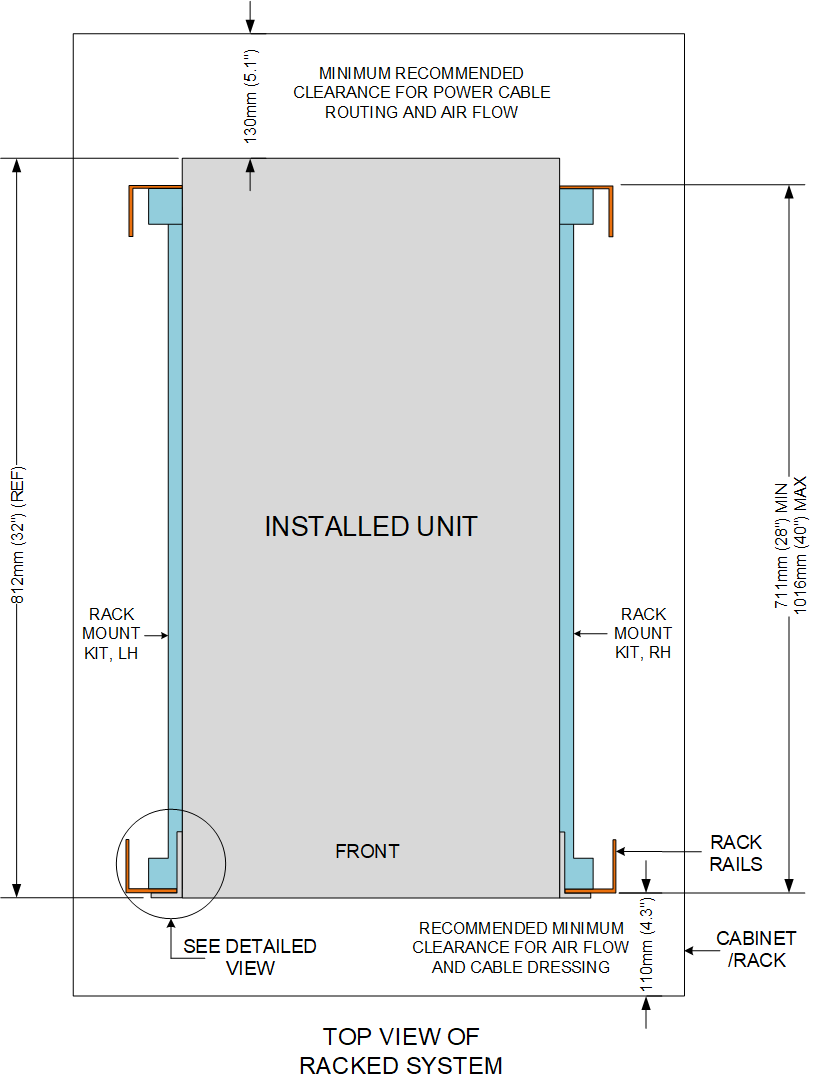

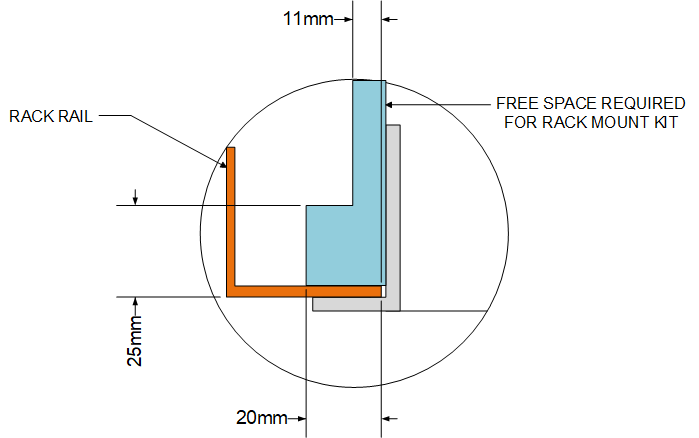

Chassis rack-mount spatial requirements

The VELOS Series platforms ship with a rack

mount kit to help install the system more easily. This kit requires that the rack

or cabinet has certain clearances and spacing, as shown here.

Rack mounting spatial requirements for the

VELOS Series platforms

Detailed view of rack mounting spatial

requirements

Platform power and airflow

The system installation needs to consider the power and air flow

specifications of all installed equipment to ensure proper cooling.

Although the maximum specifications for the VELOS CX Series chassis are

listed here, the actual power and airflow vary depending on how the system

is configured, the operating load, and the operating environment.

Chassis |

Max power |

Max airflow |

CX410 |

~5500W |

~711 cfm |

CX1610 |

~16500W |

~2845 cfm |

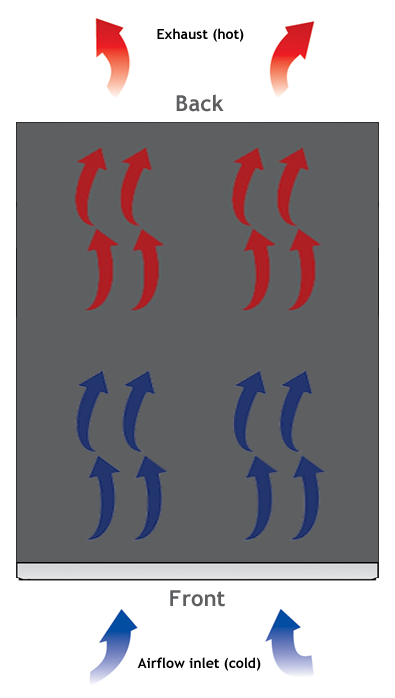

Platform airflow diagram

When you install the platform into a rack, it is

important to understand the unit's airflow direction so that you can

ensure proper cooling.

The platform employs a negative pressure fan system,

which draws cold air in from the front of the chassis.

Airflow in

VELOS

platforms